Call Us :

Cast Iron and S.G. Iron Castings

Contact : M.I.D.C, Gokul- Shirgaon | Opening Hours : 10:00 - 6:00

EST 1998

Allied Products

Allied products is a S.G iron and cast iron components manufacturer with integrated casting and machining facilities.

With an experienced team and the latest technologies, we have expertise in manufacturing a wide variety of components ranging from 50 grams in weight to 15 kilograms.

The company was established in 1998 and we have been delivering high-quality components to over 300+ customers globally.

Our lean setup allows us to cater to the changing market requirements.

Our drive for excellent production practices and customer satisfaction has made us a preferred component manufacturer by our customers.

We are making continuous technological and systemic improvements in order to implement INDUSTRY 4.0 in our organization.

2 Wheeler Components

3 Wheeler Components

Commercial Vehicles Parts

Tractors Components

Compressors Components

Valves Components

Allied Products has been a dependable manufacturer of cast iron and S.G. iron castings in Kolhapur. With over 20 years of experience in iron castings and hundreds of satisfied customers, we have been delivering high quality small casting solutions. Over the years, we have learned the essentials of providing reliable SG iron castings, making us a trusted partner for our clients.

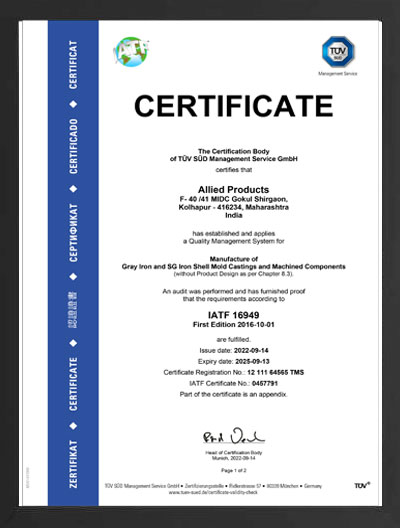

Owing to our dedication and commitment to excellence, we have received ISO 9001:2015 certification.

Our Legacy

Experts in shell mould castings, we at Allied Products have been a go-to manufacturer of small castings. Over the last 20 years, we have catered to many customers, developing over 1500 components of almost all Ferrous castings grades & for different requirements. Our strength lies in manufacturing of precision castings by shell molding & to machined it as per requirement.

Our commitment to quality is unwavering, and we make sure that we always deliver excellent casting solutions to all our clients. With an experienced and skilled manpower, we strict to stringent production guidelines, ensuring minimal wastage with maximum efficiency in all our processes. To keep our team growing and improving continuously, we empower our employees with need based training and development programs.

Low Volume, Complex Precision

Superior quality material, effective control at every step of the process, and capabilities to manufacture small batches adds to the precision and efficiency of our molding facility. We work with very less metal pouring time. This helps us to achieve the desired micro structure and physical properties of all the casings we manufacture.

Latest Technology Control Systems

The Foundry process data Controlling Software is central software that records necessary data at every step of the production process at Allied Products. It records and analyses data from production processes, it is quite helpful in components traceability purpose.

We work with complete mould handling system which covers every step from molding to knockout of casting, and sand disposal. Not only does this enhance the efficiency and cost-effectiveness of our clients, it also keeps our shop floor clean and dust free.

To know more about Allied Products, our cast iron offerings, or for any other query, you can call us on (+91-9822878541) or write to us at (alliedproduct@rediffmail.com).

Compact yet Powerful Setup

When it comes to small castings, we know what to do. Our compact setup allows us to produce small size castings (even less than 1.0 kg), and in small batches as well. This makes us an ideal partner for all your cast iron molding requirements. The compact molten pouring system delivers high pouring accuracy, and maintains metal temperature up to the last mould.

Due to small, compact set up and effective controls at every process, there is superior material quality of each casting. Due to small batches, metal pouring time is very less and we can assure every casting with desired microstructure and better physical properties. This makes our set up is most preferred source for small castings. It is needless to say we get excellent dimensional accuracy due to shell moulding. We can proudly say that we have replaced a few investment castings & Forgings as cost effective solution.

Since our inception, we’ve been focusing on manufacturing of Ductile Iron and Cast Iron castings using shell moulding. Over the years, not only have we mastered the process of shell mould casting, we have also gained expertise over time and material management. It is the combined expertise of our equipment, skilled workforce, and latest technology systems that we can now manufacture castings in less time, with less wastage/discards, and in small batch quantities without losing on quality and finishing.

-

01

Better Castings with Superior Machining Qualities

Unlike green sand, permanent mold and die casting which have hard skin and soft interior

-

02

Less Weight, Less Cost

A standard shell molding job requires

0.040 to 0.060 stocks which is considerably lower than other alternatives. -

03

Smoother Finish

Shell molding gives a smoother and

improved surface compared to sand castings.